Climate Change Adaptation and Greenhouse Gas Emissions

The Company is aware of the climate change impact on the environment, society, politics, and the economy. This inevitably impacts its business operations. As a result, the Company conducted a risk and likelihood analysis of climate change and managed its business operations to align with the Company’s and Thailand’s greenhouse gas emission reduction targets.

Management Approach

The Company established the Sustainable Development and Innovation Working Team to oversee environmental, social, and governance sustainability management and monitor climate change, greenhouse gas emissions, energy, and resources. The Company establishes targets and strategies for greenhouse gas emissions reduction and drives to manage resource consumption effectively to align with policies and achieve its goals. Each year, a Corporate Carbon Footprint working team prepares the carbon footprint of the organization (CFO) to obtain a certification from the Greenhouse Gas Management Organization (Public Organization).

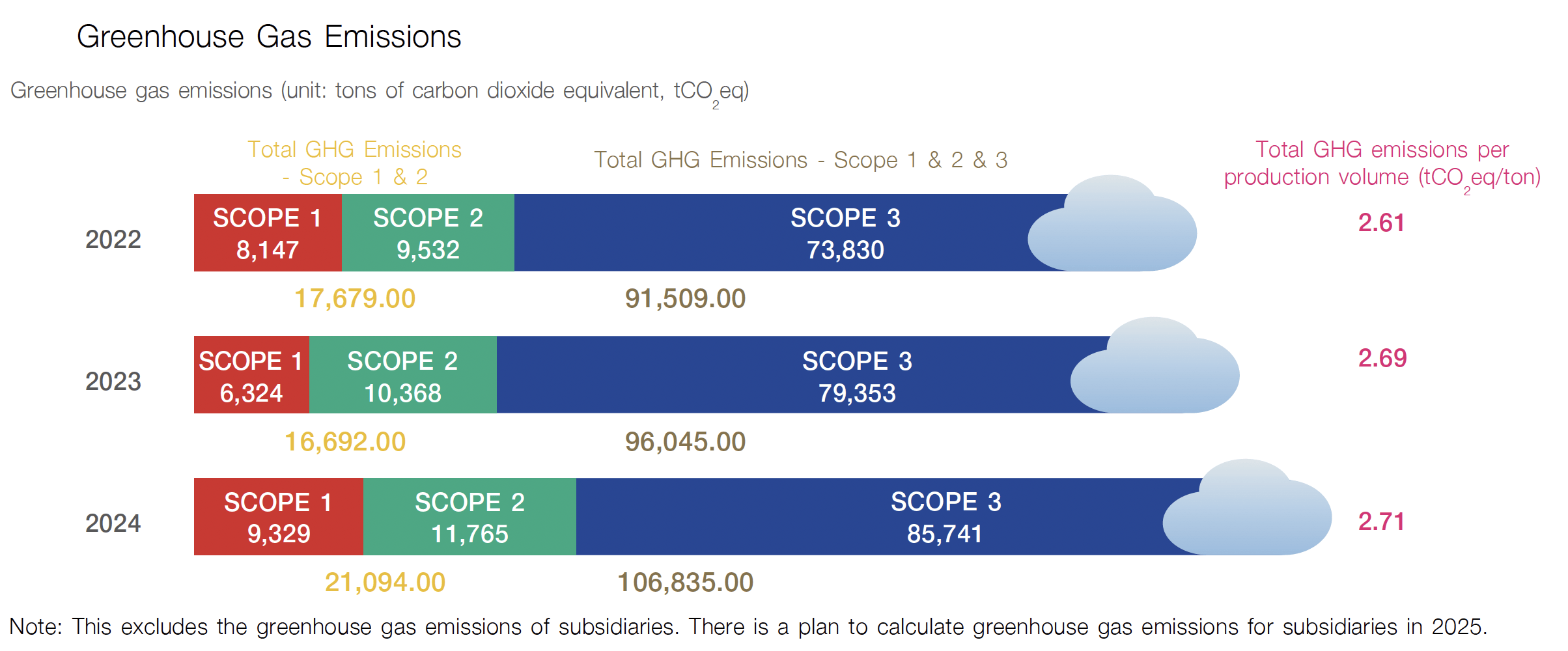

Disclosure of Greenhouse Gas Emissions

The Company has prepared data to assess the corporate carbon footprint of Thepharak Factory, Bang Phli Factory, the headquarters, Bang Na Branch, and distribution centers in Chiang Mai, Khon Kaen, and Surat Thani. This assessment covers all 3 scopes of greenhouse gas emissions in accordance with the Greenhouse Gas Emission Accounting and Reporting Standards. Prior to the disclosure of the greenhouse gas emissions, the collected data undergoes a verification process for accuracy, a registered verifier certified by the Thailand Greenhouse Gas Management Organization (Public Organization). This process has been conducted annually for each branch since 2022. The Company received the carbon footprint of the organization: CFO certification from the Thailand Greenhouse Gas Management Organization (TGO). This certification is renewed annually.

In 2024, the Company consolidated greenhouse gas emissions data from all branches into a single corporate-wide emissions account. This approach ensures accurate reporting, reflecting the Company’s actual emissions and activities while preventing double counting of inter-branch operations and verified by VGreen KU Company Limited.

Greenhouse Gas Emissions Targets

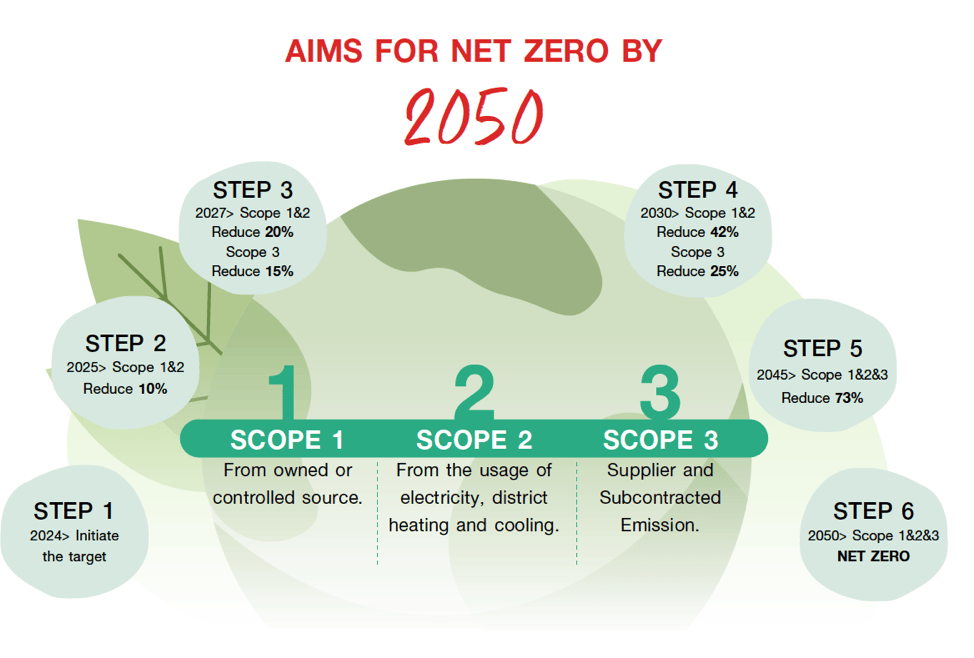

The Company sets a target for the reduction of greenhouse gas emissions from the base year in accordance with the Science Based Targets initiative (SBTi), using the SBTi Tool to set both short- and long-term targets in Scope 1, 2, and 3, and establishing a Net Zero Action plan to support the near-term and long-term targets as follows:

Near-Term Targets:

- Reduce Scope 1 and 2 greenhouse gas emissions by 10% by 2025, using 2024 as the base year.

- Reduce Scope 1 and 2 emissions by 20% and Scope 3 emissions by 15% by 2027, using 2024 as the base year.

Long-Term Target:

- Achieve Net Zero greenhouse gas emissions by 2050, with 2024 as the base year.

The Company is actively planning its transition toward Net Zero emissions in both the short- and long-term, following its Net Zero Target and Roadmap. By 2025, the focus is on energy and waste management to achieve a 10% reduction in Scope 1 & 2 within its own operations from the base year 2024 and find a strategic approach to reduce Scope 3 emissions, which may require strengthened collaboration with suppliers.

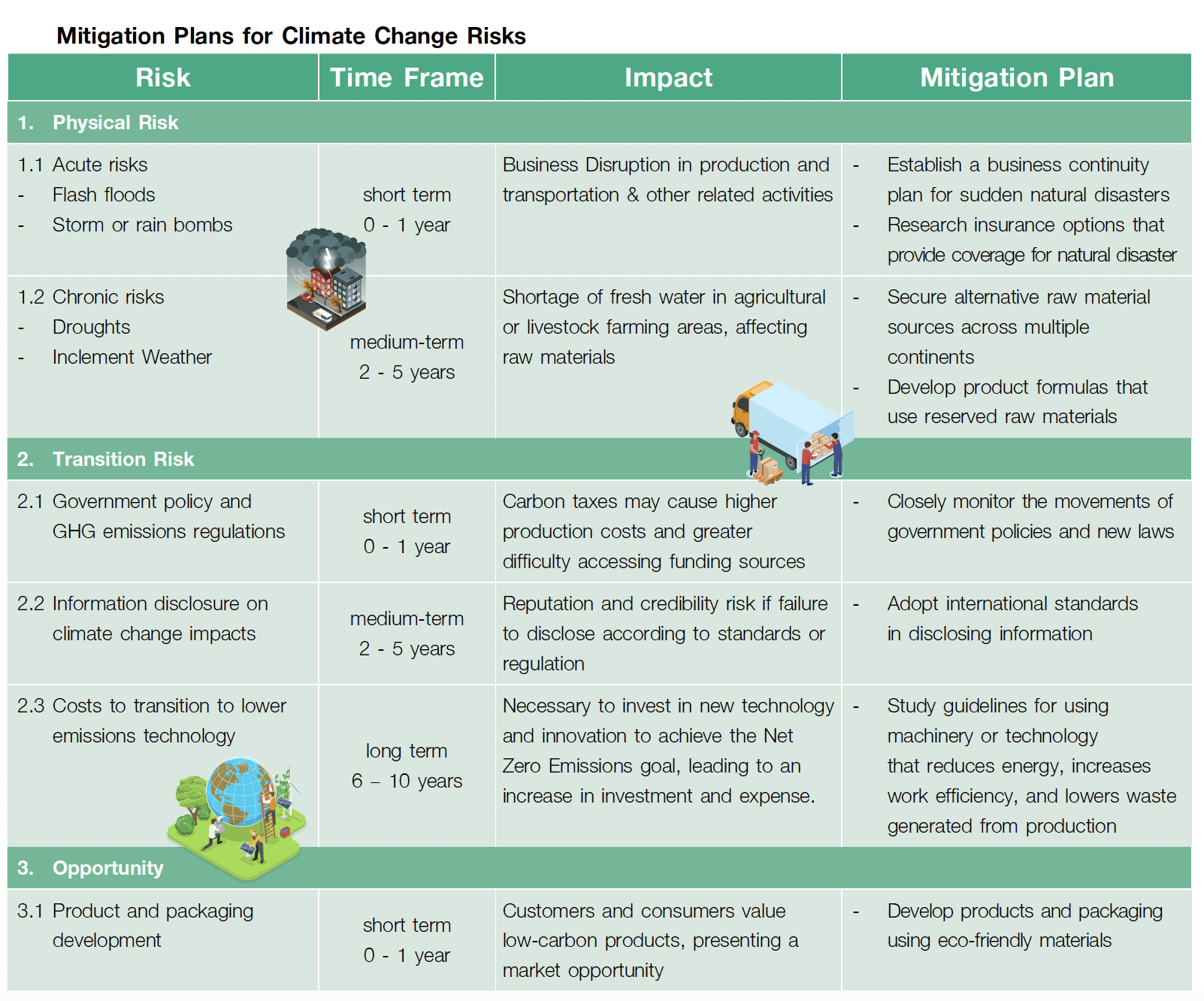

Climate Change Risk Management

The Company has assessed climate change risks based on the Task Force on Climate-Related Financial Disclosures (TCFD) guidelines to identify and evaluate its impacts on operations in all dimensions, analyzing risks and risk likelihood from physical risks, which are natural disasters such as flash floods, storms, infectious diseases in plants and animals, rain bombs, and chronic disasters such as droughts in agricultural or livestock farming areas that may impact key raw materials which affect the Company’s performance, business disruption in the production and transportation as well as the tendency of higher production costs of agricultural raw materials. This includes transition risks such as government policies, carbon pricing regulation, and information on climate change impacts, which may lead to reputation risks if targets are not achieved. Additionally, there are opportunities to develop products and packaging with innovations or new technologies. The Company incorporates these risks into its strategic planning to further develop an appropriate mitigation plan.

Greenhouse Gas Emission Reduction Management

Performance Results

In 2024, the Company’s Scope 1 and 2 greenhouse gas emissions totaled 21,094 tCO2eq, while the total greenhouse gas emissions (Scope 1, 2, and 3) amounted to 106,835 tCO2eq, reflecting an 20.9% and 10.1% increase from 2023, respectively. This rise is attributed to the launching of KCG Logistics Park, which serves as both a distribution center and a warehouse, replacing the previous external warehouse rental, moreover the usage of renovation at Theparak factory. As a result, energy consumption increased compared to the previous year. When comparing to the production capacity, the greenhouse gas emissions per production unit was 2.7,1 an increase of 0.9% from the previous year. The highest percentage of the Company’s greenhouse gas emissions are from Scope 3, which represents 80% of the total greenhouse gas emissions.

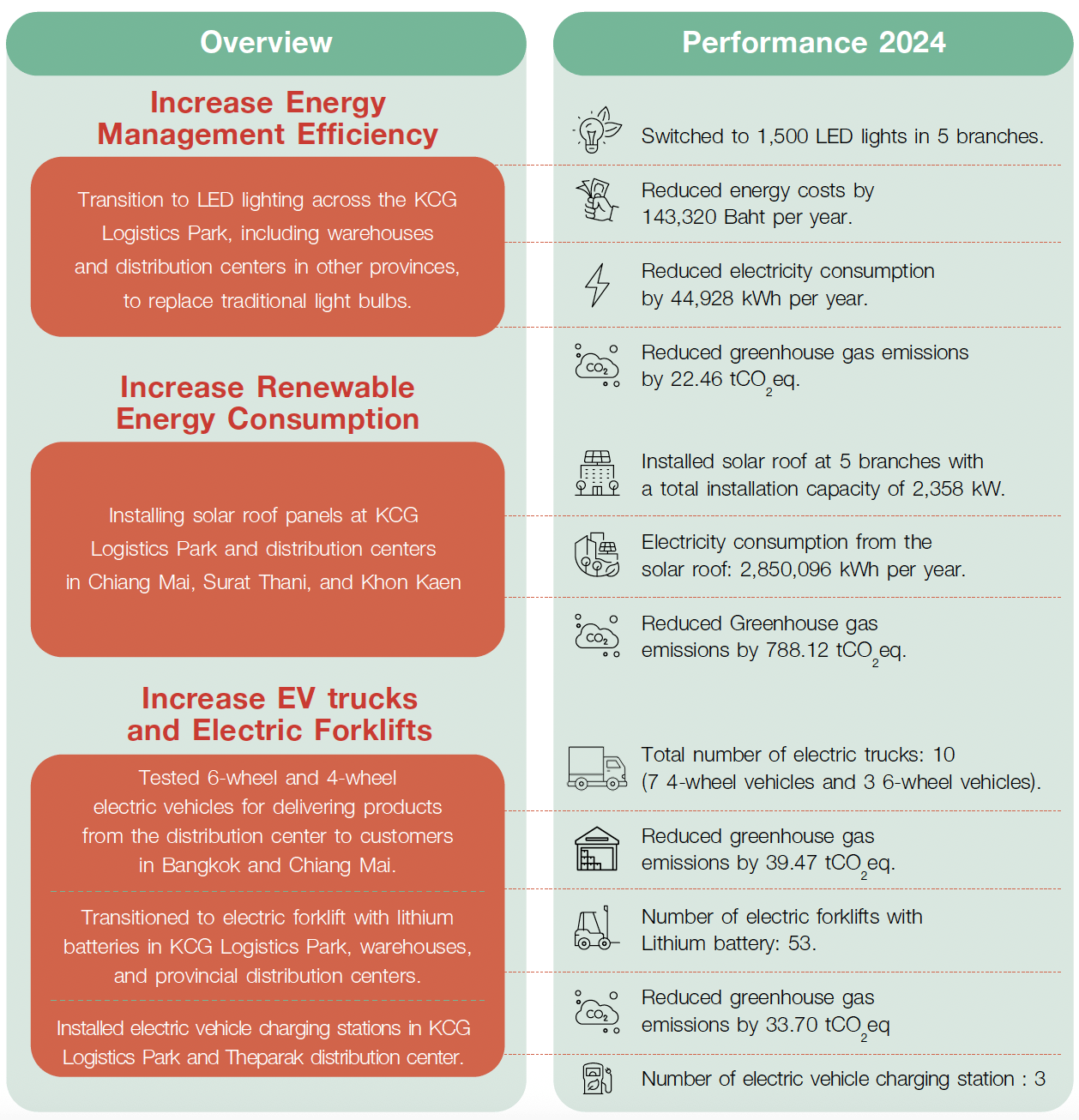

Green Logistics

The Company implemented environmental and supply chain management plans aimed at reducing greenhouse gas emissions by increasing the use of renewable energy, particularly solar energy, and improving supply chain management, especially in transportation and storage, under the concept of Green Logistics in order to support environmental strategies and energy management to reduce greenhouse gases. The projects are as follows:

Transition to LED lighting across the KCG Logistics Park, including warehouses and distribution centers in other provinces, to replace traditional light bulbs.

Installing solar roof panels at KCG Logistics Park and distribution centers in Chiang Mai, Surat Thani, and Khon Kaen

Gradually transition to electric forklifts, replacing traditional gas-powered models to reduce greenhouse gas emissions. Additionally, electric forklifts do not produce smoke or exhaust fumes which helps reduce air pollution and enhances safety for employees as there is no need to store fuel which is a flammable substance that can cause a fire.

Develop Eco-Friendly Packaging.

The Company has taken steps to increase the proportion of environmentally friendly packaging and maintain product quality by changing the type of packaging materials to be more environmentally friendly, such as changing plastic materials that decompose difficulty to biodegradable types that are easier to decompose or materials that can be recycled. Reducing the amount of material used, such as optimizing the size and characteristics of cardboard boxes, protecting the product completely during transportation, and a project to study and reduce the thickness of steel used in canned packaging. The Company has a plan to adjust the plastic film packaging group to be a single type of plastic (Mono Material) that can be separated and entered into the recycling process more easily. There is a plan to communicate the symbol of recycling through packaging. Currently, more than 61% of all the packaging used for the Company’s products can be recycled.

Sustainability Performance Data 2024 - Environmental Performance