Energy and Resource Management

The Company recognizes the significance of management and action plans in developing and improving methods for maximizing resource utilization and minimizing the consumption of fossil energy, electricity, fuel (oil, gas), water management, and any resources used in its operations. The Company aims to increase the use of alternative or renewable energy sources and raise employee awareness of energy conservation, aligning with sustainable development goals and the organization’s sustainable energy management objectives.

Management Approach

The Company is dedicated to environmental care and actively oversees and monitors operations to ensure an effective environmental management system at both the Theparak and Bang Phli factories. This includes promoting energy conservation and environmental care activities. The Company has implemented an environmental management system based on the ISO14001:2015 standards, which address resource utilization, pollution control, and the Green Industry

Level 4: Green Culture criteria set by the Department of Industrial Works. Furthermore, the Company has established an energy management policy and formed an Energy Management Working Team, comprising representatives from various departments to collaborate on promoting energy conservation and efficient resource utilization to be in accordance with the policies and achieve the set goals as follows:

- Implement and develop effective energy and resource management systems. Ensure that energy and water conservation are an essential part of the Company’s operations in compliance with relevant laws and regulations.

- Improve technology and operational guidelines to achieve optimal energy and resource utilization.

- Set energy and resource conservation plans and goals each year and communicate them to all employees to ensure their comprehension and implementation.

- Instill energy conservation responsibility in the management and employees at all levels, ensuring cooperation and compliance with established measures, while monitoring progress and reporting to the Energy and Resource Management Team.

- Provide necessary support, including human resources, budget, time, training, and opportunities for employees to contribute ideas for improving energy and the cost-effective use of resources.

- Executives and the Energy Management Working Team review and update energy and resource management policies, goals, and operational plans annually.

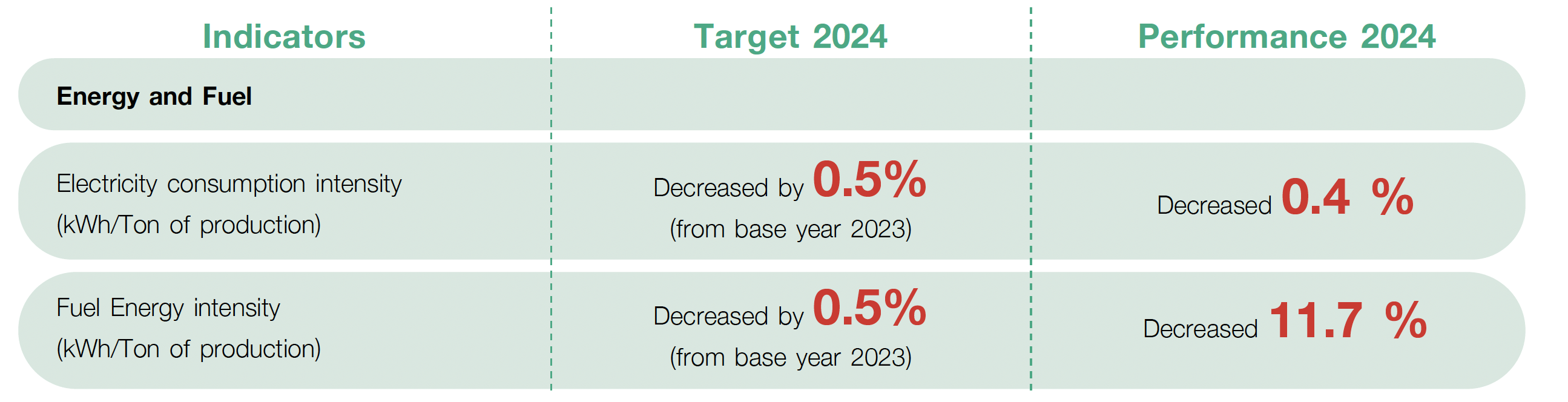

Target and Performance of Energy and Resource Management

Energy and Fuel Management

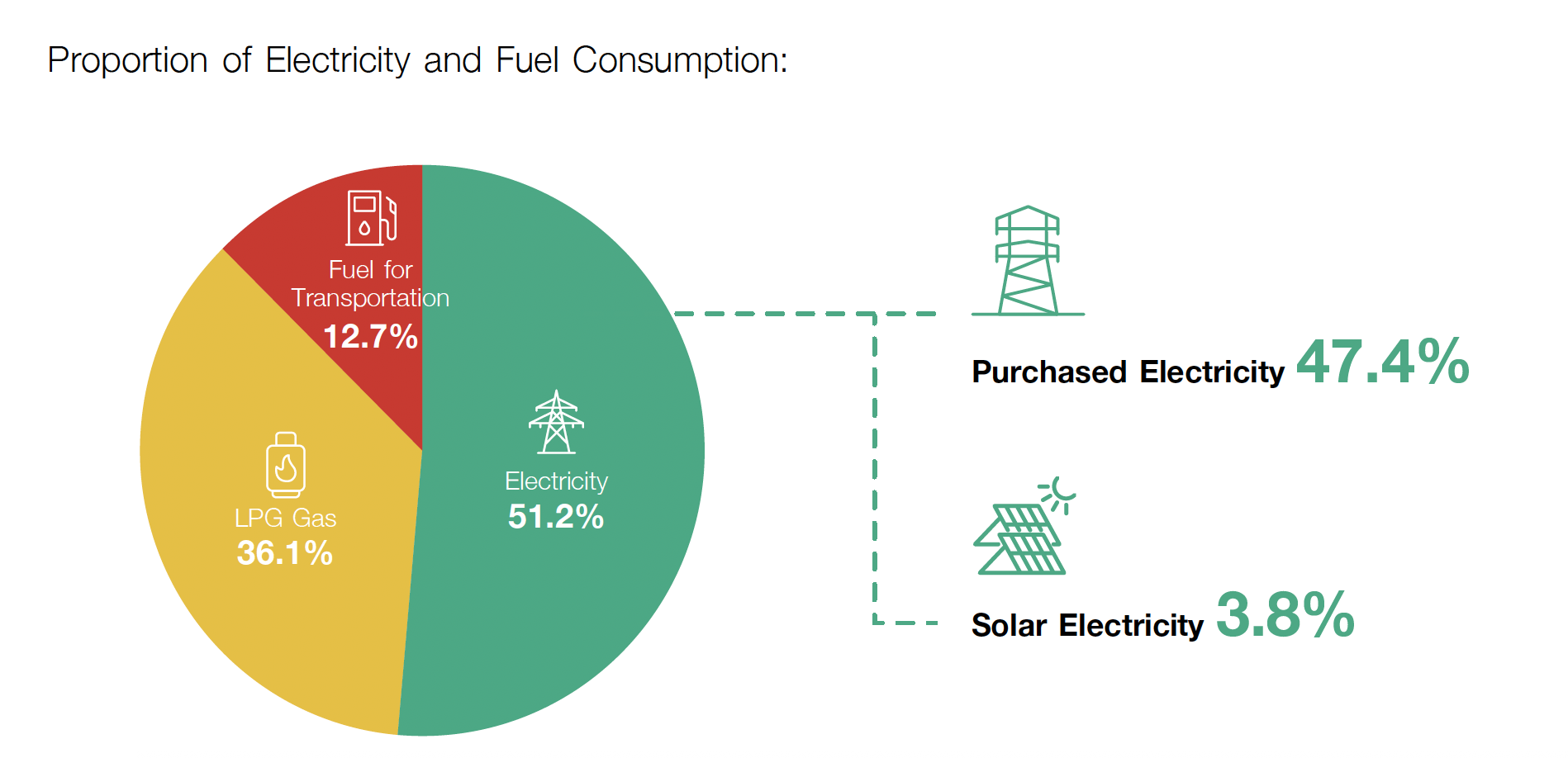

The Company consumes a substantial amount of electrical energy and fuel, particularly cooking gas in the production process and transportation, which accounted for 51.2%, 36.1%, and 12.7%, respectively. The launch of KCG Logistics Park and the renovation of the Thepharak factory in 2024 led to an increase in energy consumption, including electricity and other energy sources. However, the increase in total electricity consumption was offset by the use of solar energy generated from newly installed Solar Roof systems at five locations. Additionally, the company has implemented electricity management and energy conservation measures to optimize energy usage consistently.

Energy and Fuel Management Projects

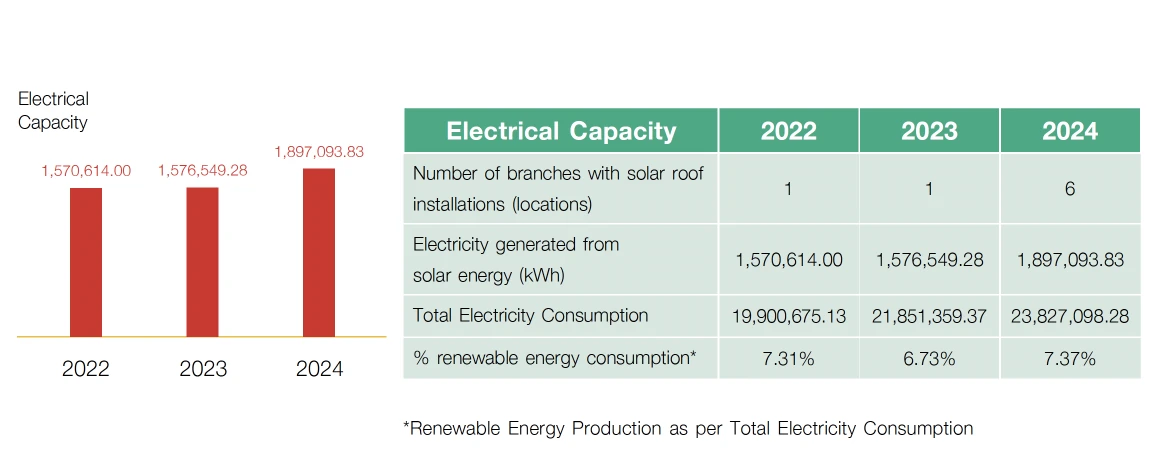

Solar Roof Installation Project at Logistics Park and Distribution Center

The Company strives to be a Green Organization that drives Thai businesses toward a low-carbon society. Since 2020, the Company has begun to use renewable energy by installing solar roofs at the Theparak factory, which has a capacity of 1,107 kW. In 2024, the project was expanded with an additional 2,358 kW capacity to increase renewable energy capacity and reduce electricity purchases.

This expansion covers all five factories and distribution centers, including the Bang Phli factory, KCG Logistics Park, and three distribution centers in Chiang Mai, Surat Thani, and Khon Kaen. The installation was completed and became operational in November 2024. Once fully functional, the system will generate approximately 4,564,489 kWh per year across all locations, resulting in an increased renewable energy consumption in 2025.

Electricity generated from solar energy (kWh)

In 2024, electricity consumption from the newly installed power generation system began in November resulting in a 20.3% increase in renewable energy production. The electricity consumption increased significantly due to the construction and testing of the refrigeration systems at KCG Logistics Park. As a result, the proportion of renewable energy consumption in 2024 increased to 7.37% from 6.73% in 2023. Solar rooftop electricity generation is expected to increase further in 2025 as it reaches full operational capacity.

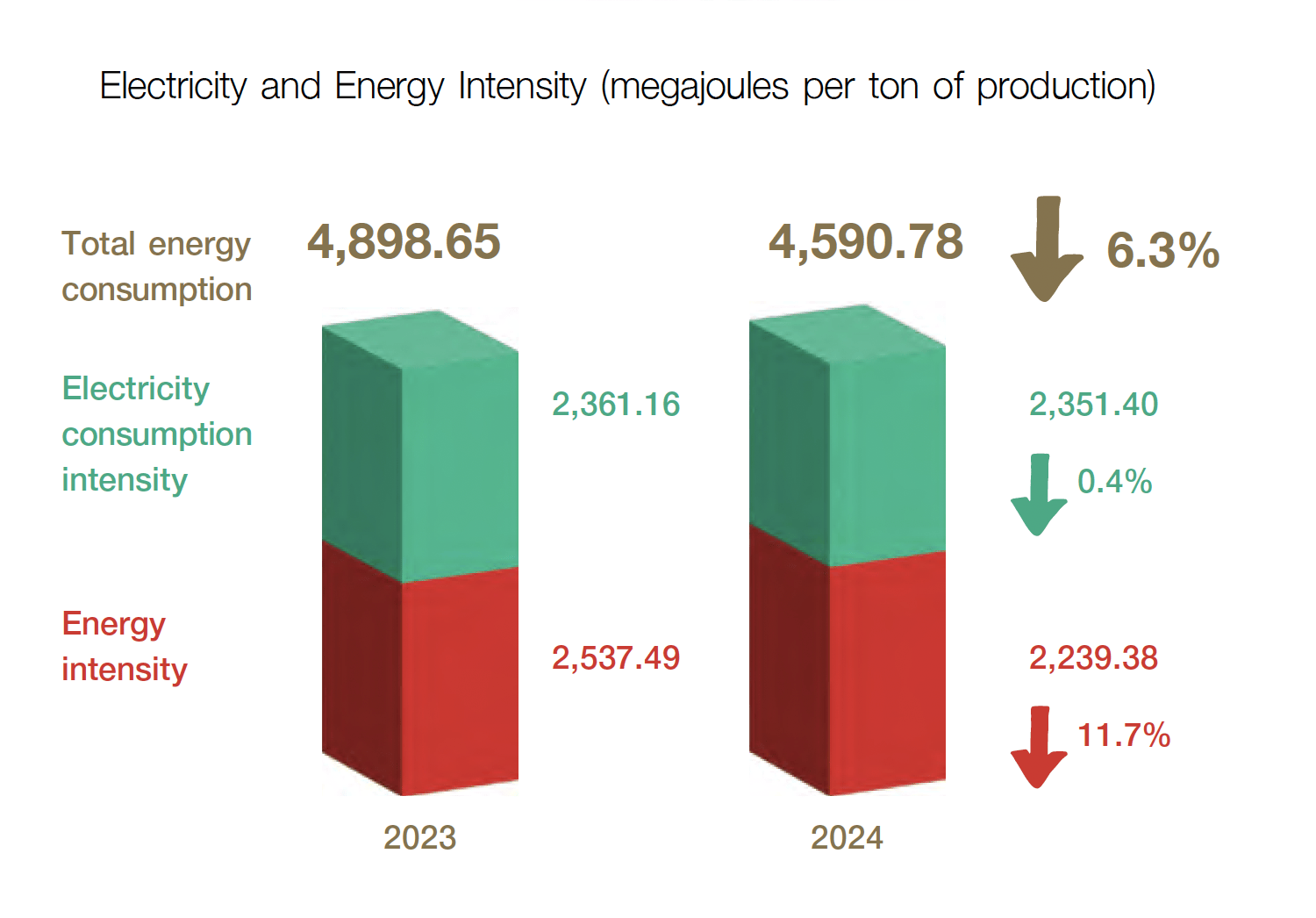

Overview of the Company’s Electricity and Energy Management

In 2024, electricity consumption per unit of production decreased by 0.4% compared to 2023. Meanwhile, fuel consumption per unit of production (including LPG and fuel for transportation) declined by 11.7%, leading to an overall reduction of 6.3% in total energy consumption per unit of production.

Water Management

The Company has established water consumption guidelines based on sustainable methods and is committed to continuously improving water management. The Company sources water responsibly, ensuring it does not harm surrounding communities and is mindful of the growing global water challenges. The Company prioritizes environmental impact mitigation through effective water management in its production and service activities, ensuring compliance with the standards, laws, and Notifications of the Ministry of Industry regarding Industrial Effluent Standards B.E. 2560. Additionally, the Company is continuously focused on finding ways to use water recycling within its operations to maximize its utility.

Water Risk Management Approach

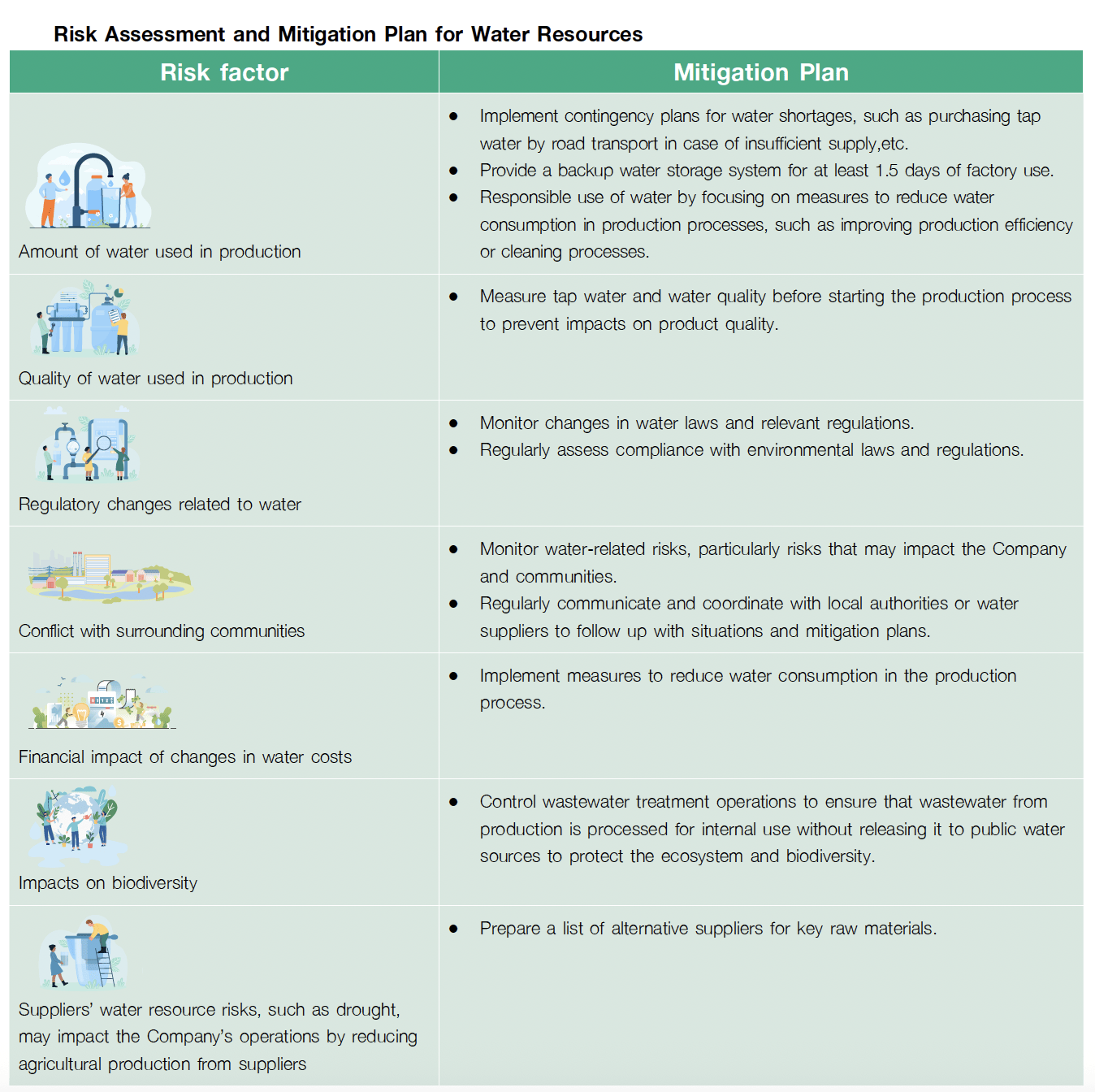

The Company prioritizes water resource management due to the significant water consumption in its operations and production processes. Substantial amounts of water are required for various activities, and wastewater from the production may pollute natural water sources and harm the environment. These impacts may affect the livelihoods of surrounding communities and biodiversity in water sources and contribute to natural disasters such as droughts or seawater surges caused by global warming. Therefore, the Company is committed to improving processes to reduce water consumption and maximize the efficient use of resources while planning for effective wastewater management. The mitigation plan for risk management of water resources is as follows:

Target and Performance of Water Management

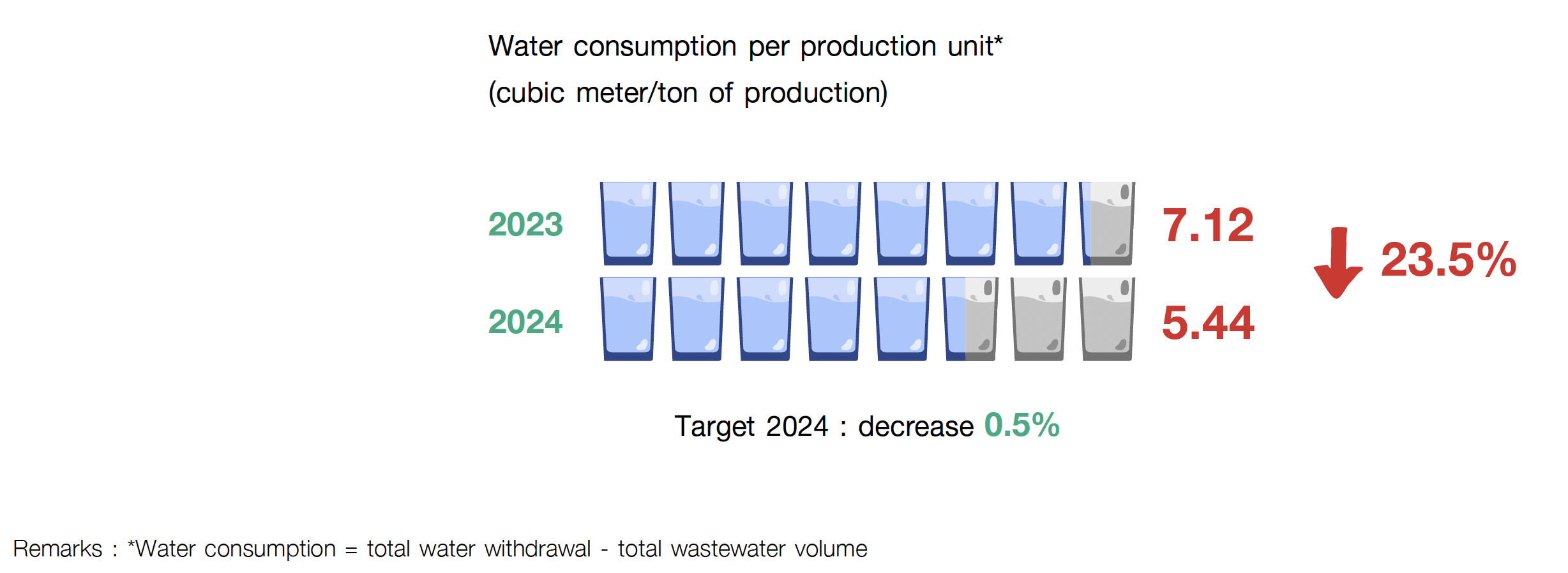

In 2024, the Company had sufficient water resources with no production disruptions or impacts on product quality due to water issues. The Company complied with all water-related laws and received no complaints from surrounding communities. Additionally, the Company achieved a 23.5% reduction in water consumption per production unit compared to 2023, surpassing the target and decreasing water costs.(Target 2024 is a 0.5% decrease in the reduction of water consumption intensity)

Water Recycling

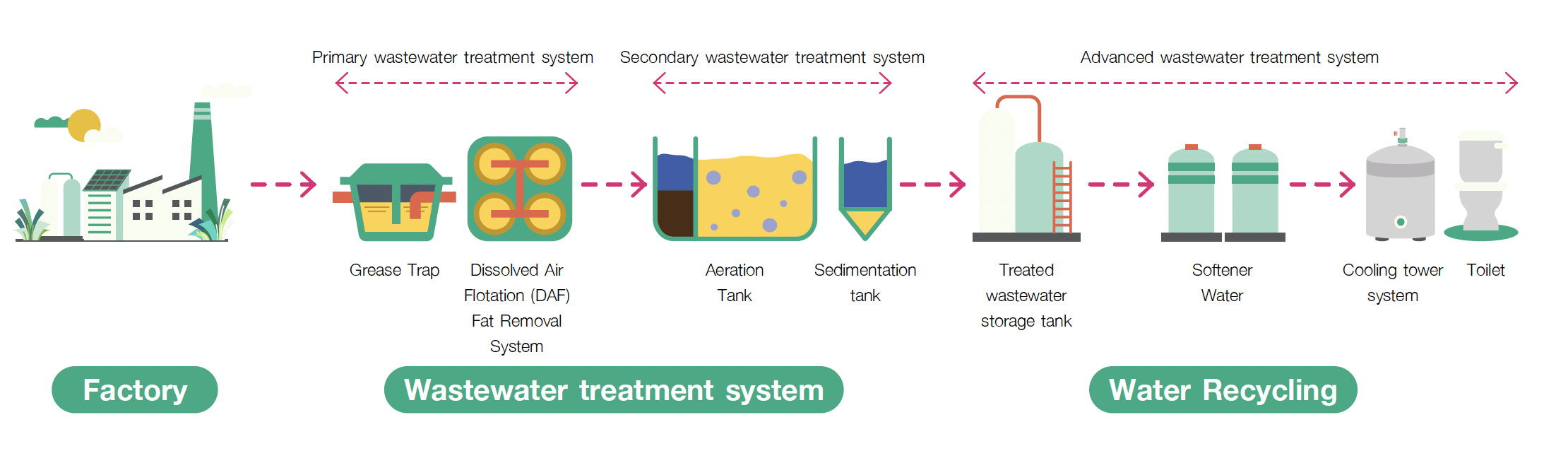

The Company manages wastewater treatment alongside water resource conservation to minimize tap water usage. This involves designing and selecting wastewater treatment systems suitable to the specific characteristics of wastewater

generated at each factory, ensuring effective pollution control and treatment. The treated wastewater is then reused within the factory for non-production activities, ensuring no impact on product quality and enhancing overall water

management. This was done to maximize water management and improve its efficiency within the factory. Currently, each factory follows the water and wastewater management processes as follows:

-

Theparak Factory - Wastewater from the factory enters the treatment system, where it undergoes an initial disposal or treatment process using a grease trap and dissolved air flotation (DAF). It is then sent to the second stage of the treatment, utilizing the activated sludge (AS) biological treatment system and sequence batch reactor (SBR) treatment system until the wastewater meets legal standards. After treatment, the water is of sufficient quality for reuse. The treated wastewater is directed into the softener water system and is used in the cooling tower system and for bathroom toilets.

- Bang Phli Factory - Wastewater from the factory enters the treatment system, beginning with the initial removal or treatment process using grease purification and grease trap. It is then sent to the second stage of treatment, where the activated sludge (AS) biological treatment system is used. This system includes three aeration tanks providing sufficient air for wastewater treatment, following the flow direction diagram, until the wastewater meets legal standards.The treated wastewater is stored in the Company’s water tank and reused for activities such as watering trees, washing road surfaces, etc.

Wastewater Quality Control

In addition to installing an efficient wastewater treatment system, the Company has established a monthly monitoring schedule for the quality of treated wastewater. A certified private analytical laboratory, under ISO/IEC 17025 standards, is hired to randomly collect water samples entering and exiting the treatment system for analysis. This ensures the monitoring of wastewater quality and the efficiency of the treatment systems. The monitoring parameters and measurements are based on the Notifications of the Ministry of Industry regarding Industrial Effluent Standards B.E. 2560.

Key Projects of Energy and Resource Management More information on other highlight energy and resource management projects is available in KCG Sustainability Report 2024

Sustainability Performance Data 2024 - Environmental Performance