Sustainable and Responsible Supply Chain Management

The Company values sustainable supply chain management and has made it a primary business strategy, with a commitment to manage efficient supply chain and enhancing the Company’s potential to achieve its goals, as well as managing potential environmental, social, and economic impacts from any business operations of the Company, its suppliers, or stakeholders in the supply chain. As a result, the Company conducts supplier sustainability assessment and supports suppliers to have good corporate governance to reduce operational risks from economic, social, and environmental impacts. The Company values supplier engagement in potential development and new innovations to jointly strengthen its competitiveness and advantages across the supply chain, leading to mutual sustainability.

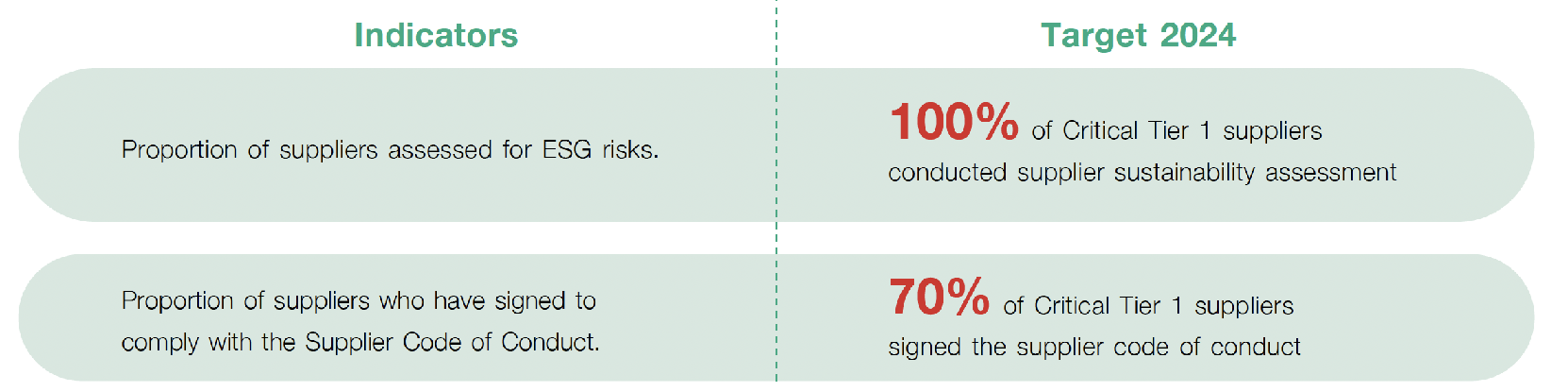

Target and Performance of Sustainable and Responsible Supply Chain Management

Supply Chain Management Strategy

Management Approach and Relevant Policies

The Company recognizes that the operations of any supplier can impact overall goals, not only in economic terms, but also in social and environmental dimensions, such as raw material and product safety, regulatory violations, human rights violations, pollution, and environmental issues, including increased greenhouse gas emissions, waste management, and safety of life and property, etc. The Company established policies for the sustainable supply chain management and integrated supplier management into relevant operations by identifying critical suppliers and classifying those with high ESG risks. This approach aims to mitigate supplier risks and foster a unified effort toward Environment, Social, and Governance (ESG).

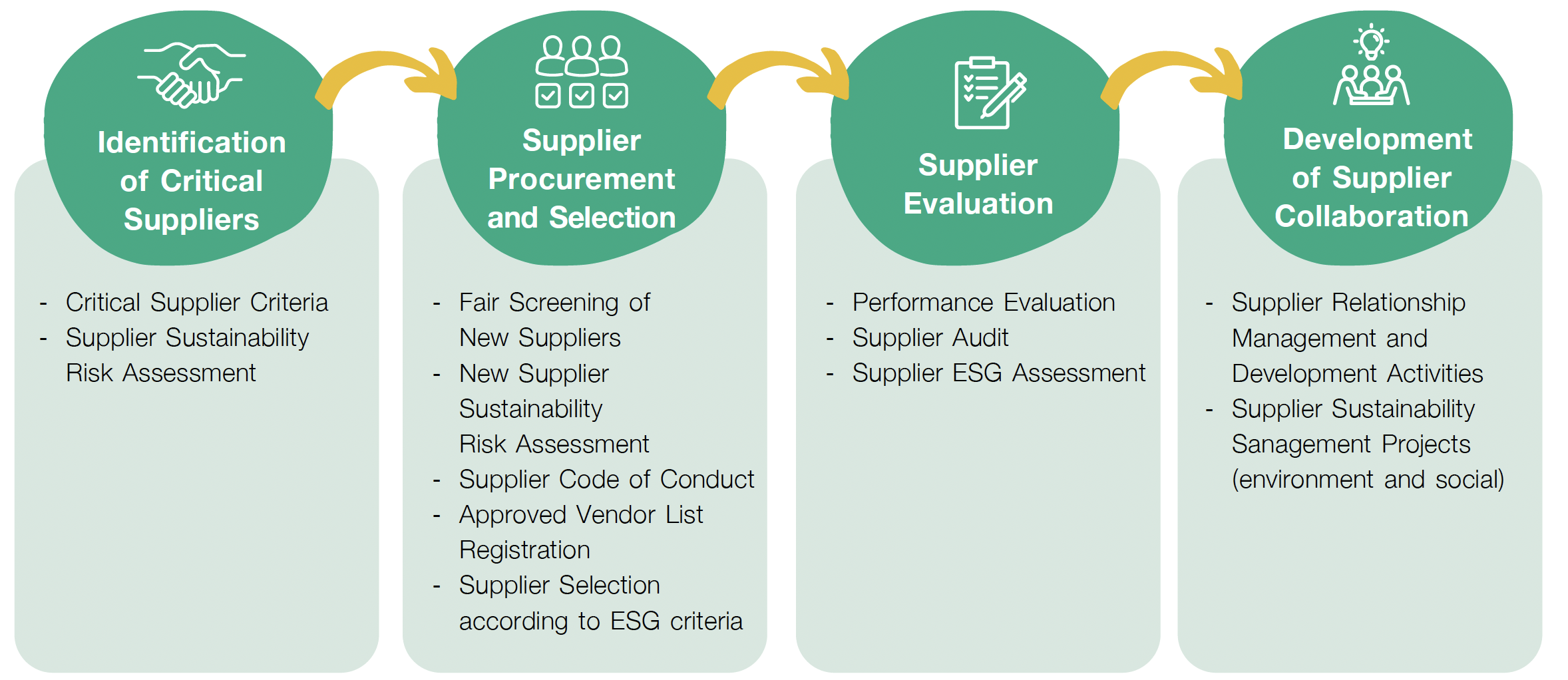

Sustainable Supply Chain Management

The Company manages its suppliers in accordance with the sustainable supply chain management policy as follows:

Key Partner Classification

- Setting Criteria and Identifying Critical SuppliersTo evaluate the significance of suppliers, the Company has established classification criteria to clearly identify critical suppliers, determine their importance, and assess sustainability risks and manage suppliers appropriately. The criteria are as follows

1. Critical Tier 1 Suppliers are key suppliers that conduct business directly with the Company and meet the following criteria:

- The value of raw material purchases is within the top 80% of the Company’s total annual purchase value.

- Supply essential raw materials crucial to the Company’s operations, for which no replacements are available.

- Pose ESG risks, such as environmental impacts, labor violations, or vulnerabilities related to climate change.

2. Critical Non-Tier 1 Suppliers Critical Non-Tier 1 Suppliers are key suppliers that do not conduct business directly with the Company but have an impact on the Company’s operations. This includes manufacturers or producers of raw materials and copyright owners of products sold to the Company through agents.

Critical Supplier and High-Risk Supplier

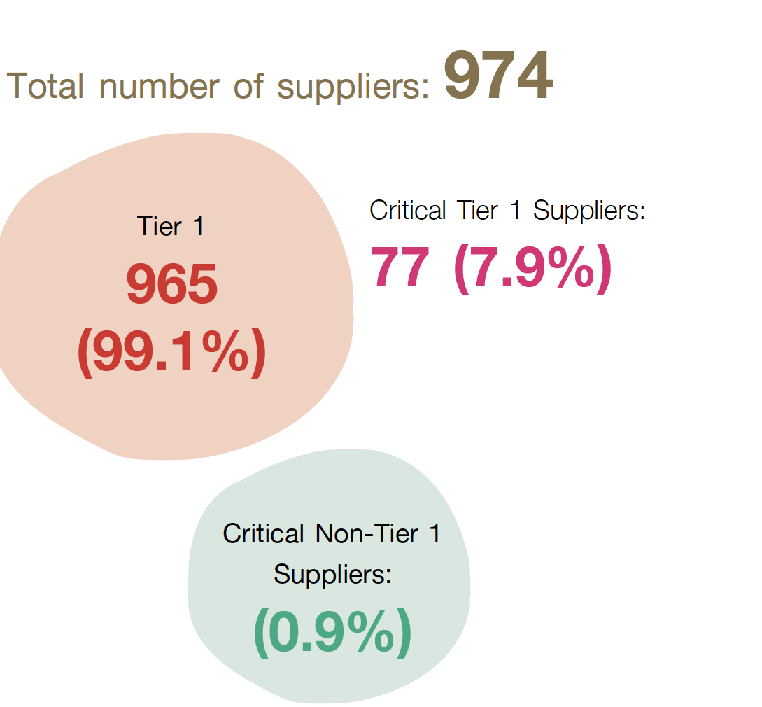

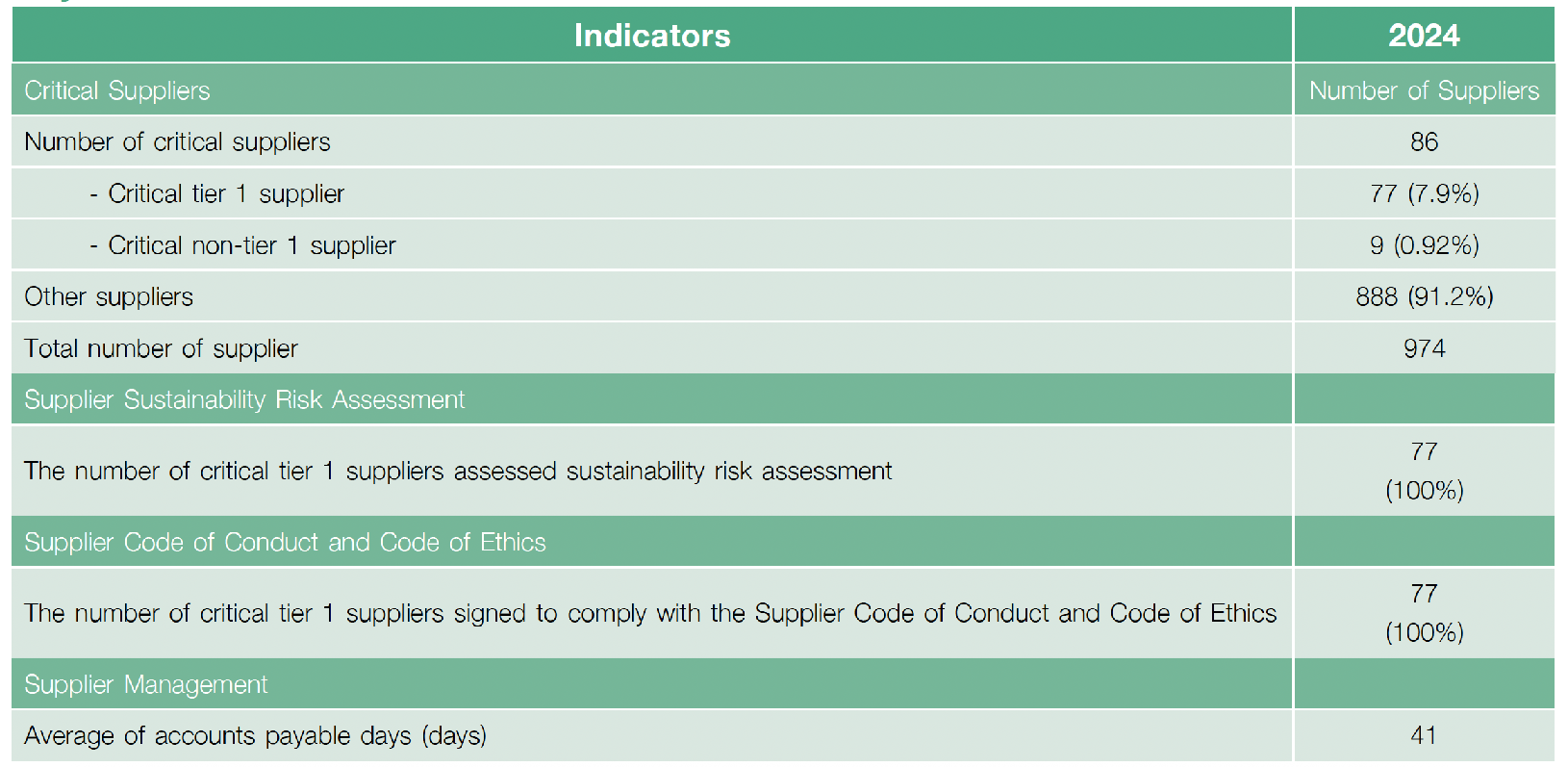

In 2024, Critical Tier 1 Suppliers, who conduct business directly with the Company, accounted for 7.9% of the total suppliers.

The Critical Non-Tier 1 Suppliers, who indirectly conduct business with the Company, accounted for 0.9%. The 2024 risk assessment of critical suppliers found no high-risk suppliers. As a result, on-site assessments were not conducted.

New Partner Registration and Selection

Supplier Procurement and Selection

The Company prioritizes fair and transparent procurement and selection of new suppliers, as well as setting the evaluation criteria for supplier audit and sustainability assessment. The Company has an e-procurement system that enables suppliers to complete applications and submit essential supporting documents. This system is designed to safeguard data security and ensure the confidentiality of supplier information. The information received is used solely for trading or supplier management activities, ensuring data protection and preventing data breach or misuse of information.

The criteria for selecting new suppliers include a business score based on factors such as product characteristics in accordance with industrial standards, production, capacity, quality management, delivery capabilities, and business sustainability, including social and environmental issues.

The purchasing department considers the evaluation results of the sustainability self-assessment of new suppliers, and supporting documents for the Approved Vendor List.

- Supplier Code of Conduct

The Company established a Supplier Code of Conduct to ensure suppliers understand and adhere to sustainable best practices.

The Company prepared the Supplier Code of Conduct and Code of Ethics which includes material topics such as code of ethics, community and environmental responsibility, human rights, occupational health and safety, and etc. This aimed to serve as sustainability guidelines for suppliers.

New suppliers must acknowledge and sign the Supplier Code of Conduct and Supplier Code of Ethics. The Company plans to expand the process of disclosing the supplier Code of Conduct and supplier Code of Ethics, fostering cooperation to implement the Code of Conduct across all suppliers in each group

In 2024, the Company developed a Code of Conduct and a Code of Ethics, and began distributing them to 100% of Critical Tier 1 Suppliers, as per the set target. Plans are in place to have new suppliers sign an acknowledgment, with the aim of expanding this initiative to include all supplier groups

Responsible and Sustainable Sourcing of Key Raw Meterials

Supplier Evaluation

The Company conducts annual supplier post-evaluations. If evaluation results do not meet the specified criteria, suppliers must take corrective action within a set timeframe. If improvements are not with the criteria, the Company will consult with suppliers and explore alternative measures for improvement.

As for supplier audit, the Company prepared an annual on-site assessment. The assessment identifies operational inefficiencies and areas for improvement in quality systems and the food production safety standards framework. These issues are monitored until resolved. Suppliers that pose high ESG risks are closely monitored. If these risks stem from suppliers and cannot be mitigated, or pose potential impact on the Company, new measures may be considered or exploring alternatives suppliers.

The Company intends to improve its ESG risk assessment criteria by including ESG risk assessments in its annual supplier audit to further enhance ESG risk assessments of new suppliers. A pilot assessment was conducted with Critical Tier 1 suppliers. The results will be used to study relevant international regulations and standards to review and improve ESG assessment criteria for all suppliers in the long run.

Supplier Sustainability Risk Assessment

The Company assesses supplier risks that may impact both the economic and ESG dimensions, including:

- Environmental risks, such as waste and pollution management, and noncompliance with environmental laws.

- Social risks, such as human rights violations, occupational health and safety, and personal data security.

- Governance and Economic risks such as corruption, ethical disputes, etc.

The Company requires suppliers to assess sustainability risks through self-assessments and purchasers, using publicly available evidence for foreign suppliers or interview their references. Guidelines have been established for high-risk suppliers to have an on-site assessment at their facilities. If an on-site assessment is not feasible, an online meeting must be arranged promptly to determine a risk mitigation plan.

Sustainable and Responsible Major Raw Material Sourcing

The Company has additional requirements for the major raw material sourcing, including dairy products (butter oil, cheese and powdered milk), palm oil products, wheat flour, and sugar, ensuring that they come from sustainable and responsible sources.

- Dairy Products: The Company primarily

imports raw materials for dairy products from Australia and New Zealand, which are global critical suppliers with upstream dairy farm management that prioritize animal welfare and comply with national and international laws and standards such as the Australian Animal Welfare Standards and Guidelines for Cattle and the New Zealand Animal Welfare (Cattle) Code of Welfare. Several critical suppliers adhere to the animal welfare guidelines set by the World Organization for Animal Welfare. This ensures that KCG’s imported dairy products are certified, meet international animal welfare standards, and have a traceability and verification system.

- Palm Oil Products: The Company sources

palm oil from RSPO-certified (Roundtable on Sustainable Palm Oil) suppliers or from suppliers with a traceability and verification system, ensuring it is not sourced from suppliers associated with environmental or social harm, such as encroachment or deforestation. Instead, suppliers must prioritize sustainable cultivation, biodiversity preservation, reduced pesticide use, responsible water resource management, and ethical labor practices that respect human rights and ensure that the production of palm oil products meets customer needs while consistently upholding environmental responsibility.

- Wheat Flour: The Company imports wheat

flour from abroad, where agricultural industry standards for pesticide management and government agricultural development policies may differ. Therefore, wheat flour products must have a traceability and verification system that identifies their original agricultural source. Suppliers must implement manufacturing processes that prevent the mixing of wheat from different sources, ensuring that all delivered wheat flour is fully traceable to its origin.

- Sugar

is produced domestically under the regulatory framework of the Sugarcane and Sugar Act. Suppliers must comply with all relevant laws, regulations, and guidelines while upholding responsibility throughout the supply chain. In addition to having a sustainability policy, suppliers must demonstrate care and commitment to farmers, production processes, and product delivery in alignment with sustainability guidelines. Suppliers must have a policy promoting the harvesting of fresh sugarcane, providing farmers with knowledge and support to enhance the ecosystem of sustainable sugarcane cultivation. Sugarcane planting areas must not be subject to encroachment or deforestation but follow sustainable farming practices that support biodiversity, implement responsible chemical, insecticide, and pesticide controls, manage water resources effectively, uphold ethical labor practices, and respect human rights.

In 2024, all critical suppliers in the major raw materials group complied with the additional sourcing requirements. No significant risk issues were identified; therefore, on-site assessment was not conducted.

- Green Procurement Policy

The Company established the Green Procurement Policy and developed a Green Procurement Manual to source eco-friendly products and services in accordance with the criteria and qualifications specified for each product category. This aims to raise supplier awareness of environmental responsibility and promote the efficient use of resources throughout the product life cycle. The Company prioritizes the procurement of products or services that are the most environmentally friendly, while also ensuring suitability, effectiveness, and reasonable pricing. This includes items such as electrical appliances, office equipment, computers, electronic devices, vehicles, advertisements, public relations services, electrical and construction products, cleaning services, etc.

Development of Supplier Collaboration

The Company prioritized collaborating with suppliers on product, services, and packaging development, as well as promoting potential and sustainable business operation with suppliers by carrying out the following projects.

- Annual Supplier Meeting

Since 2019, the Company has held the KCG Corporation Suppliers Day, an annual supplier meeting, to communicate policies and business direction and foster sustainable relationships with suppliers. This annual event provides a forum for communication, knowledge exchange, and developing new ideas. This includes fostering business collaboration and promoting sustainable development throughout the supply chain, such as minimizing environmental impact or adhering to social responsibility standards.

In 2024, KCG Corporation Supplier Day was held on February 6, 2024. The event was attended by over 130 suppliers representing 75 different companies. The Company communicates its sustainability policy and the potential for improved supply chain management through the Logistics Park, providing concrete examples such as the use of EV trucks and the Backhauling Project to reduce waste from return trips. These serve as guidelines for suppliers to adopt similar activities and work towards achieving shared sustainability goals. Furthermore, a seminar on sustainability was held by inviting suppliers who excel in environmental operations, such as Thanakorn Vegetable Oil Products Company Limited, known for “COOK soybean oil,” which was the first company awarded with the Green Industry Level 5 for the vegetable oil category to share the journey towards green industry certification. United Container Company Limited (UCC) shared its extensive experience as a supplier with the Company and worked together to develop sustainability through the Green Innovation project with the Company in developing eco-friendly packaging such as butter and bakery products. This set a precedent for other suppliers to join the Company in sustainability development.

Policies and average payment terms for suppliers

The Company is committed to strictly adhering to the terms and conditions of payment agreements with suppliers, accounts payable and receivables. The accounting and finance department processes payments through banking channels, ensuring suppliers receive timely payments. Accounts payable days may differ depending on the product, business type, or commercial conditions. The credit terms determine the accounts payable days as agreed upon with suppliers, depending on various factors such as the nature of the business, the longevity of the partnership, and any other relevant factors. The average accounts payable days is approximately 60 days. The Company has defined and communicated the accounts payable days to its suppliers. In the event of an emergency or other situation that may cause payment delays, the Company will promptly notify the suppliers, explain the reasons, and reschedule the payment as needed, either immediately or in advance, depending on the circumstances.

Key Performance

More information on other Sustainable and Responsible Supply Chain Management

KCG Sustainability Report 2024

Sustainability Performance Data 2024 – Governance and Economic Performance