Occupational Health and Safety

The Company has acknowledged the occupational health and safety standards and created a safety culture under the occupational health and safety policy. The Company is dedicated to ensuring the well-being of employees and all stakeholders across its supply chain, providing a hygienic and safe working environment. The Company recognizes that every activity carries risks of accidents resulting from unsafe actions and unsafe conditions which could lead to injury, illness, property damage, or disruptions to critical production processes that affect the Company’s operation and its competitiveness.

Management Approach and Relevant Policies

The Company established occupational health and safety policies and guidelines that focus on awareness and potential development among employees and executives, as well as external parties engaging in activities within the Company’s premises. In 2024, the Company advanced its occupational health and safety management by obtaining certification for ISO 45001:2018 standards for the Occupational Health and Safety Management System.

As a manufacturer, service provider, and distributor of quality food products, both domestically and internationally, the Company recognizes that occupational health and safety is a crucial element for successful business operations. Therefore, the Company has established the following management guidelines:

- Complying with laws, regulations, and international standards, as well as having a commitment related to occupational health and safety working environment.

- Reduce risks and prevent hazards associated with illness, occupational diseases, fires, chemicals, electricity, and accidents that could lead to loss of life, property damage, production disruptions, or transportation issues in alignment with objectives and the time frame. Determine business continuity measures to protect the organization from security threats with strict security protocols.

- Communicate performance and effectiveness of occupational health and safety operations to both internal and external stakeholders in a transparent manner.

- Executives at all levels are expected to lead by example, providing support, time, budget, and relevant training. Supervisors must serve as positive role models, ensuring all employees understand and follow safety procedures.

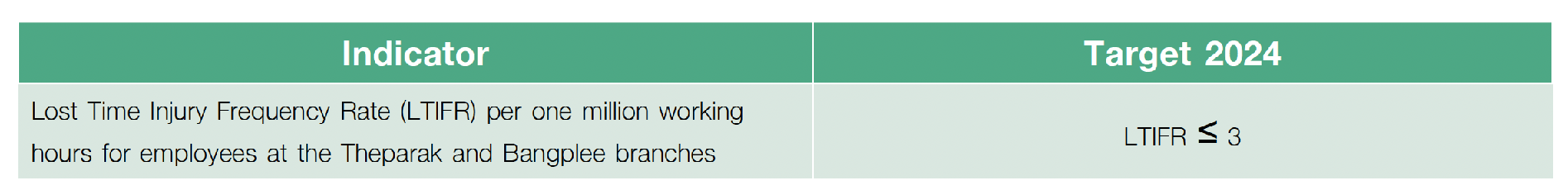

Target and Performance of Occupational Health and Safety

In 2024, the Employee Lost Time Injury Frequency Rate (LTIFR) per one million hours worked was 6.62, not met the target 2024. As a result, the Company has conducted a thorough investigation to identify the root causes and improve work processes for greater safety. This includes implementing measures to strengthen the safety culture and tangible measures to control and lower work-related risks.

Key Action Plans

1. Occupational Health and Safety Risk Assessment and Mitigation Planning

To ensure comprehensive and efficient occupational health and safety operations, the Company adopts hazard identification and risk assessment to analyze risks and risk likelihood that cover all work activities of employees, contractors, and external parties for normal events and emergency situations, leading to the formation of risk mitigation plans, risk control plans, and continuous improvement plans.

2. Emergency Management

The Company is confident in its preparedness for various emergency situations and ensures that safety equipment is available throughout the organization. Several drills and training programs are conducted annually, including fire evacuation drills, basic fire extinguishing training, chemical or gas pipeline leak drills, and evacuation drills for ammonia leaks in the production process or cooling process. The Company regularly communicates evacuation procedures and ensures that any visitors or outsiders participating in activities or tours within the organization are informed of safety protocols.

3. Work Environment Inspection

Conduct environment and work safety assessments according to the plan. If any standards are not met, improvements and systematic monitoring will be implemented. The process includes:

1. Survey the work environment with active work activities in each area and identify risk factors as follows:

- Chemical environment

- Physical environment

- Biological environment

The risk factors harmful to health include heat stress, Wet Bulb Globe Temperature (WBGT), light, noise, and chemical agents.

2. Measure and assess Indoor air quality: Establish measurement, analysis, and compare the results with legal standards or guidelines from recognized institutions or organizations. Prepare reports, feedback, and recommendations for further control and prevention measures.

4. Promoting and Cultivating a Safety Culture

The Company has consistently promoted safety operations, emphasizing employee participation in creating a safety culture by conducting hazard identification activities through Safety Committee representatives from each work area, who work together to proactively identify risks on a weekly basis, leading to effective safety problem-solving in the workplace. Additionally, other safety promotion activities are organized, such as safety training for employees, Morning Talk sessions, and Safety & Environment Day events. These activities provide safety knowledge in various forms, fostering a safety culture within the organization.

Sustainability Performance Data 2024 - Social Performance